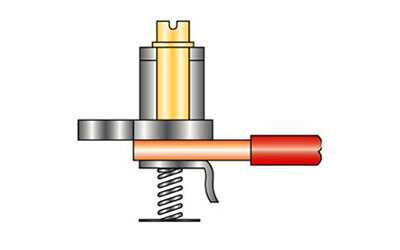

Vibrations adversely affect terminal connection, causing loosening of conductors and consequent overheating of terminal blocks. elmex Terminal Blocks are therefore designed to be inherently resistant to vibrations in normal applications. However, high vibrations can arise due to vibration affected installation sites, such as installations in and around mines, proximity to heavy machine shop,forging/ die casting shops, cement/steel plants machinery, textile machines and so on. Special designs for high vibration applications are also preferred in some Power Projects, Power Distribution Centers, Motor Control Centers and Relay Control Panels. depending on proximity of vibration generating equipment. elmex Standard Screw Clamp design, with compression springs, provided under the clamp, offer a reliable solution for high vibration applications of Terminal Blocks. These are called "SPRING LOADED" terminal blocks. FEED THROUGH TYPE: KST 4UWS, KST 6WS, KULT 4, KULT 6, KULT 1 DISCONNECTING TYPES: KULTD 4WS, KULTD 6 The spring is assembled under compression, so that it engages firmly with the contact clamp. For inserting the conductor, clamping screws should be unscrewed and pressed, which results into pushing down the contact clamp against spring action and creates space for conductor insertion below the current bar. When the screw is tightened with specified tightening torque,the clamping part moves to cause gripping of conductor with current bar, as with normal clamping process, but in case of spring loaded design, the conductor is gripped with additional clamping force exerted by the compression spring from below the clamping part. Special design of the current bar with a recess is available to anchor the hook bladed cable lug, in the current bar. This provision creates conductor locking within terminal block once it is clamped, so that it cannot be pulled out accidentally. This design is presently available in types KULT 1, 4, 6 and KULTD 4, 6.

Send Enquiry